Introduction

If you’ve ever worked with metal, you already know that accuracy is everything. Whether it’s aerospace, automotive, or precision machining, carbide center drills are the unsung heroes of the shop floor. But here’s the catch—your results are only as good as the tool you’re using. That’s why choosing the right manufacturer is such a big deal.

In this guide, we’ll explore the top 10 carbide center drill manufacturers worldwide, what makes them stand out, and how to pick the best one for your needs.

Why Carbide Center Drills Matter

Precision and Durability

Carbide center drills are designed to create accurate starting points for larger drills. Unlike standard high-speed steel (HSS), carbide offers exceptional hardness and heat resistance, meaning you get cleaner holes and longer tool life.

Applications in Different Industries

From aerospace components that demand micron-level accuracy to automotive engines that can’t afford errors, carbide center drills are the foundation of reliable machining. They’re also essential in die-making, energy, and general manufacturing.

Factors to Consider When Choosing a Manufacturer

Quality Standards

Always check if the company meets ISO and DIN standards. These certifications ensure you’re not dealing with subpar tools.

Range of Products

A strong manufacturer won’t just sell one or two drill types. They’ll offer a broad portfolio—from center drills to end mills, reamers, and specialty cutting tools.

Innovation and Technology

Today’s leaders invest heavily in R&D. Whether it’s nano-coatings or AI-driven tool design, innovation sets the greats apart from the rest.

Customer Support

It’s not just about selling drills—it’s about helping you succeed. Great brands provide technical guidance, training, and after-sales support.

Top 10 Carbide Center Drill Manufacturers

1. Kennametal

A giant in the cutting tool industry, Kennametal is known for its durable carbide tools that perform exceptionally well in high-demand industries like aerospace and defense. Their innovative coating technologies help extend tool life.

2. Sandvik Coromant

Headquartered in Sweden, Sandvik Coromant is a pioneer in carbide tooling. They’ve consistently led the market with smart machining solutions and sustainable practices.

3. Guhring

A German brand with more than a century of experience, Guhring manufactures some of the most precise carbide drills on the market. Their micro-drills and specialty tools are especially popular in medical and automotive applications.

4. Seco Tools

Seco Tools has built a reputation for reliable, cost-effective carbide tools. They’re widely praised for their cutting-edge geometries that reduce vibration and improve finish quality.

5. Mitsubishi Materials

Japanese engineering at its finest. Mitsubishi Materials is known for combining toughness with precision, making their center drills a top choice in high-speed machining environments.

6. OSG Corporation

Another Japanese powerhouse, OSG is world-renowned for taps, end mills, and drills. Their carbide center drills are engineered with advanced coatings and geometries for high-performance machining.

7. Dormer Pramet

This brand is popular in Europe and beyond for offering reliable carbide tooling solutions. Their balanced price-to-performance ratio makes them a go-to for many manufacturers.

8. Kyocera Precision Tools

Kyocera brings innovation to the table with ceramic-carbide blends and specialized coatings. Their focus on durability and performance makes them stand out in heavy-duty industries.

9. Sumitomo Electric

Sumitomo is a name trusted globally for cutting-edge carbide and cermet tools. Their nano-technology-driven products help improve tool wear resistance significantly.

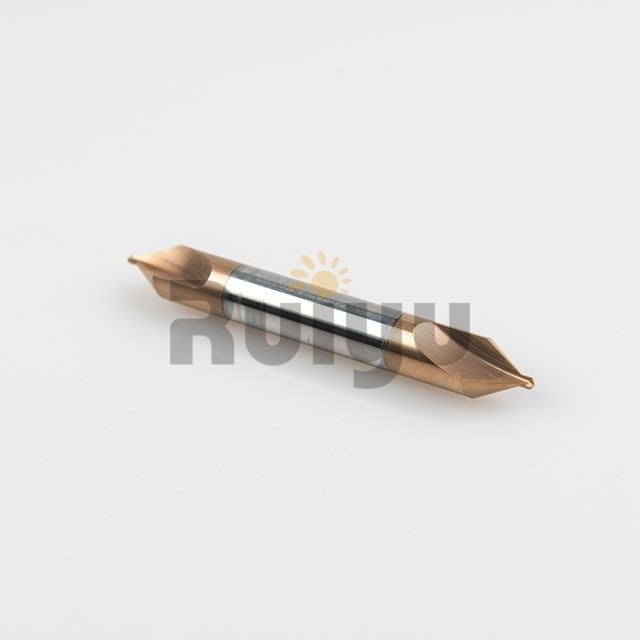

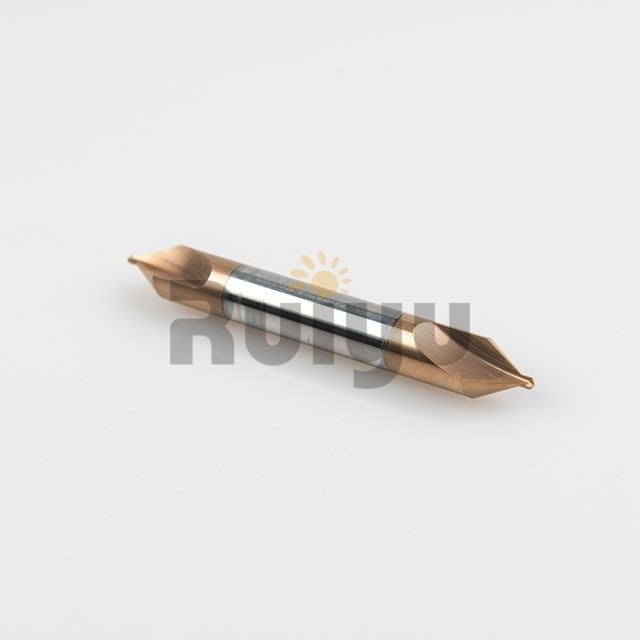

10. RUIYU Tool

Known for both robotics and cutting tools, Ruiyu combines versatility with precision. Their carbide center drills are widely used in automotive and industrial sectors.

Comparing Global Leaders vs. Regional Manufacturers

Strengths of Global Brands

Global giants like Kennametal and Sandvik invest billions in R&D, meaning their tools often set the gold standard in performance, coatings, and tool life.

Advantages of Local Suppliers

Local and regional manufacturers, on the other hand, can offer faster delivery times, lower costs, and customized solutions. For small to medium shops, this can sometimes be more valuable than global prestige.

How to Maintain Carbide Center Drills

Proper Storage

Moisture and improper handling can damage carbide tools. Always store them in protective cases or racks.

Usage Best Practices

Avoid excessive feed rates or speeds. Carbide tools are tough but brittle—think of them like glass. They’ll perform flawlessly if handled correctly.

Sharpening and Reconditioning

Instead of tossing dull tools, many manufacturers offer regrinding services that restore them to like-new condition at a fraction of the cost.

Future Trends in Carbide Drilling Tools

Advanced Coatings

Expect to see more diamond-like coatings (DLC) and nano-coatings that drastically reduce wear and increase tool life.

Smart Manufacturing Integration

With Industry 4.0, carbide tools are starting to integrate with sensors and data systems, allowing real-time monitoring of tool performance.

Sustainability in Tool Production

Green manufacturing is the future. Brands are adopting eco-friendly processes and recyclable carbide materials to reduce their environmental footprint.

Conclusion

Final Thoughts

Choosing the right carbide center drill manufacturer can feel overwhelming, but it doesn’t have to be. Whether you go with a global leader like Sandvik or RUIYU or a trusted regional supplier, the key is finding a partner that matches your quality, budget, and support needs.

Remember, in machining, the smallest detail can make the biggest difference—and your choice of center drill manufacturer is one of those details.